Reactors designated for dismantling in Sweden

Several nuclear power reactors are designated to be dismantled and demolished in Sweden in the coming years. Within two years, six Swedish reactors will be in various phases of dismantling and demolition. Of these, Uniper in Sweden is responsible for four reactors that are to be dismantled within about ten years’ time. These comprise the two reactors at Barsebäck, and Oskarshamn 1 and 2. The dismantling is being undertaken as a joint project and is implemented in set sequences. This is to maximize control and safety, and to responsibly manage the funds allocated for dismantling and demolition: the Swedish Nuclear Waste Fund (KAF).

Watch as we conduct our demolition work

The reactor is what comes to mind for most people, when talking about nuclear power. It is also the largest component in the plant. The reactor is where fission reaction takes place and where the energy that drives the process is harnessed. A Barsebäck reactor is 20 meters high, 5 meters in diameter and weighs 430 tons. When the plant was built, the reactor was brought into the facility in one piece. Each reactor takes about one year to segment and lift out.

The video clip shows how we lift out the reheater, for the dismantling and demolition of the reactors at the Barsebäck nuclear power plant. When the reheater is active, it is normally located between the high-pressure turbine and the low-pressure turbines. Although the reheater is slightly radioactive, about 95% of its materials can be decontaminated and recycled.

Plan for one – do it for four

Oskarshamn kärnkraftverk, OKG, and Barsebäck Kraft AB, will handle the radiological demolition as part of a collaborative project that is split into various work packages. A work package could, for example, involve the segmentation and removal of the reactor vessels or the removal of turbine and generator components. The main work will be conducted sequentially, i.e., such and such must first be done at one site, then at the others. This will enhance the efficiency and safety of the demolition process. The organizations of both companies will adapt to this work method and many employees will assume new roles at the sites.

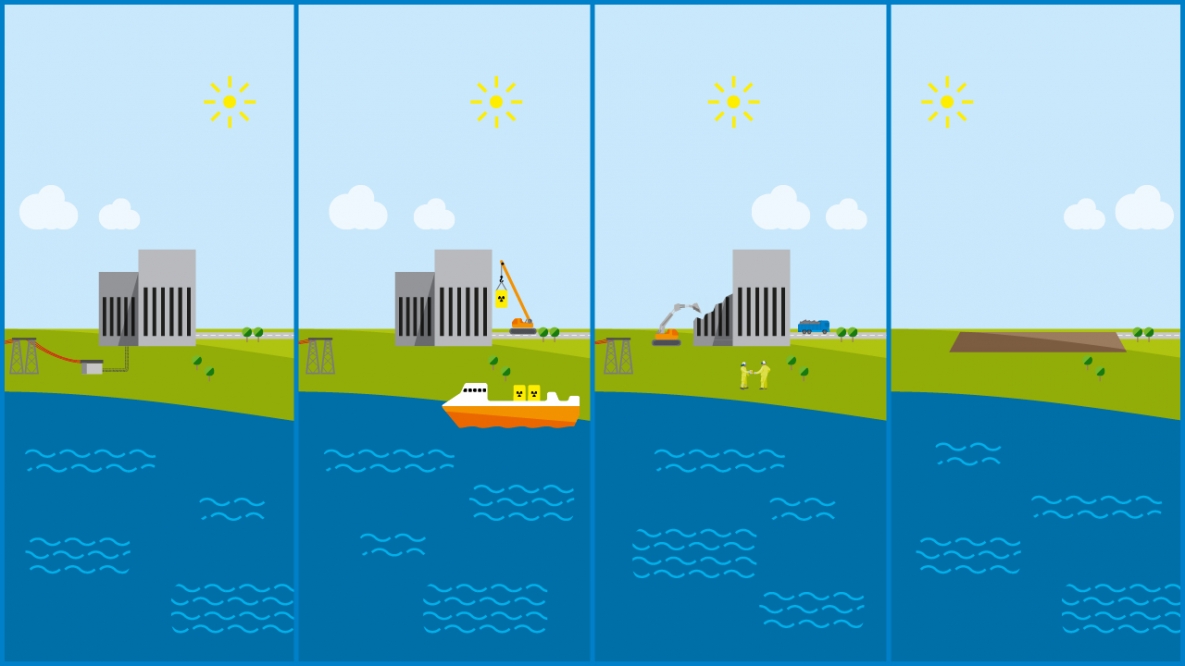

Before dismantling can begin certain preparations must be made, such as transporting all spent nuclear fuel to the shared Swedish interim storage facility in Oskarshamn. At Barsebäcksverket, the last items of nuclear fuel were removed as early as 2006. Authorizations, as well as environmental permits and new safety analyses reports must be in place. All radioactive material must first be removed before the nuclear power plant can be demolished. Plants are dismantled from the inside out, in order to remove the most radioactive materials first. These may consist of the internal components of reactor vessels and the reactor vessel itself. After these major undertakings are completed, less radioactive components, such as the turbines and generators, are next in line. A systematic review of the entire facility then follows. Concrete, metal and other materials that are also radioactive are removed in the next step. About 6% of the entire facility is radioactive and must be removed first.

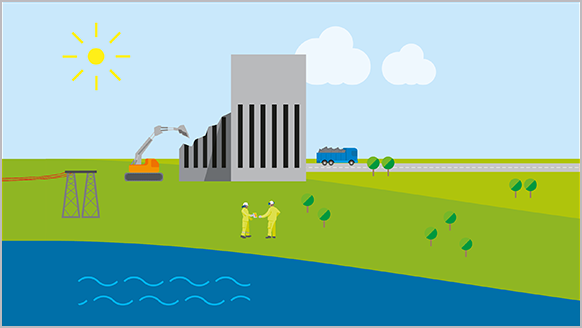

Once all the radioactive materials have been removed, the plant is classified radioactivity free. The conventional demolition of buildings then begins – the major and visible part of the work, which is several years ahead. The conventional demolition phase will be implemented in the early 2030s. Once the buildings have been demolished, the concrete will be sorted for backfill and the metal for recycling. The small amounts of asbestos and PCB that exist that will be processed pursuant to prevailing regulations.

We work proactively to transport the demolition materials in the most efficient manner possible.

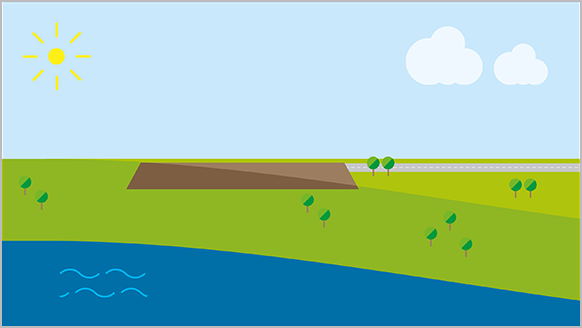

When the conventional demolition is completed the land will be restored to an industrial plot with a radiation level identical to that of the surroundings. Skåne has very low levels of natural background radiation. Uniper is the owner of the land and will subsequently make a decision about what the land should be used for in the long term. For example, the electricity grid infrastructure adjacent to the plant makes the site suitable for electricity generation.

Uniper intends to demolish the buildings and prepare the land for industrial purposes. There are no radiological obstacles to taking any additional steps to change the land’s zoning status in the long term to enable its utilization for other purposes, such as a public recreation area or residential district.

Much of the demolition waste is recyclable

Once a material that has been used in a nuclear power plant is classified radioactivity free, it can be recycled like ordinary waste. The radioactivity-free classification of materials from the Barsebäck plant contributes to the circulation of the economy. Recycling enables materials from the dismantling of a nuclear power plant to gain new life. Circular and sustainable solutions provide new resources to the market, thereby also creating value for the environment.

The land, after radioactivity-free classification and demolition

BKAB has – from a perspective of radiological protection and the radioactivity-free classification of the area – expressed the goal of “free usage” even if the ultimate goal for the area is less sensitive land use (MKM) (industrial area). What does this really entail and what do we mean? We explain this below.

Will the land be radioactive after the demolition?

BKAB’s goal upon completion of demolition, is for the land, which is earmarked for industrial use, to be restored and classified radioactivity-free. However, the target is for the land’s radioactivity levels to be the same as those of the immediate environment. It should have the same level of natural background radiation as the surrounding farmland. The level of natural background radiation in Skåne is lower than other parts of Sweden.

Radioactivity-free classification

Radioactivity-free classification refers to the Radiation Protection Act and whether nuclear operations should apply to the area. The Swedish Radiation Safety Authority (SSM) is the agency that makes decisions on the radioactivity-free classification of areas. Once such a decision is made, the holder of the land has no further obligations under the Radiation Protection Act or the Act on Nuclear Activities. The SSM is also the body that, upon receiving an application by the operator, decides on an area’s level of radioactivity-free classification, which the operator must respond to in terms of controls and decontamination measures. The radioactivity-free levels must be based on the annual effective dose that an individual from the general public can be expected to receive, because the radioactive contamination in the area must not exceed 0.1 mSv. Before an area can be classified radioactivity-free, it is checked for radioactive contaminants by means of, for example, field measurements, sampling and calculations. An area’s continued use from the perspective of radiological protection (under SSM’s radioactivity-free classification) falls under “free use” and “use with restrictions.”

Conventional contaminants

Barsebäck’s objective is for the land to be ready for industrial purposes when it is restored following demolition and radioactivity-free classification.

We must not only check for radiation, but also that there are no conventional pollutants remaining, such as fuel or other harmful substances. Land that is designated for industrial use is subject to less stringent requirements than if the land were to be used for farming or residence, for example. The level of decontamination work to be undertaken is determined by location-specific guideline values that will be announced.

Find out more

Information about how we process waste from the demolition of Barsebäcksverket.

Here is some information about Barsebäck’s environmental permits and certifications for the environment, and occupational health and safety.